SB200 series integrate the optimized high-performance space vector control VVVF algorithm which supports numerous advanced functions, e.g. auto torque boost, slip compensation, oscillation suppression, tracking startup, stall prevention, precise deadband compensation, auto voltage stabilization, process identification and auto carrier frequency adjustment. With inbuilt constant pressure water supply and clock modules, the series are suitable for most industrial control applications.

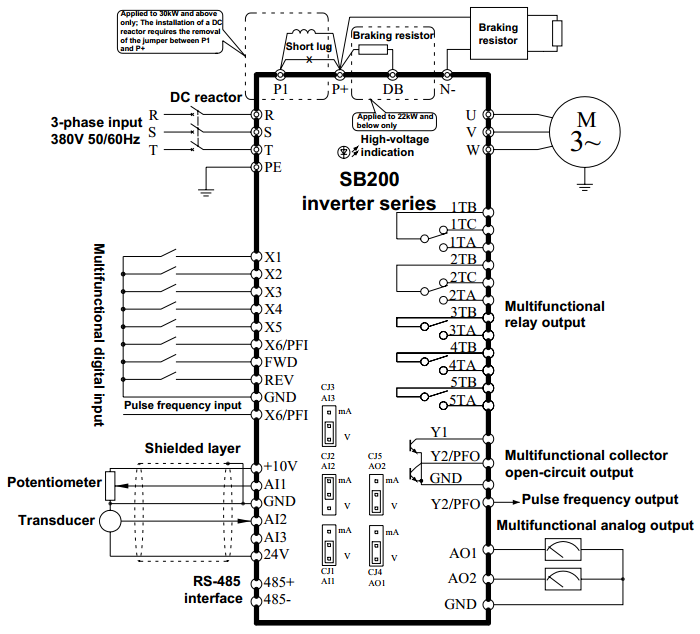

Refer to the following drawing for fundamental wiring required for operation

Universal Technical Specification of SB200 Inverter Series

Item | Description | ||

Input | Rated Voltage/Frequency | 3-phase, 380V; 50/60Hz | |

Range | Voltage: 320-420V; voltage unbalance:<3%; frequency: 47-63Hz | ||

Output | Output Voltage | 3-phase; 0v-input voltage; error: below 5% | |

Output Frequency | 0.00-650.00Hz | ||

Overload Capacity | 110% of rated current; 1 minute | ||

Frequency Resolution | Digital setting: 0.01Hz; analog setting: 0.1% of max frequency | ||

Output Frequency Accuracy | Analog setting: ±0.2% of max frequency (25±10℃); digital setting: 0.01Hz (-10—+40℃) | ||

Command Execution Channel | Settings may be configured via the control panel, control terminal or communication port. Switching is enabled via the terminal | ||

Frequency Setting Channel | Control panel, communication port, UP/DOWN adjustment, AI1, AI2, AI3 or PFI | ||

Auxiliary Frequency Setting | Flexible auxiliary frequency micro-adjustment and frequency setting synthesis | ||

Torque Elevation | Auto/manual torque elevation | ||

V/F Curve | Customizable V/F curves, linear V/F curves and 5 torque reduction characteristic curves | ||

Jogging | Jogging frequency range: 0.10-50.00Hz; jogging acceleration/deceleration time: 0.1-60.0s | ||

Auto Energy Saving | Load-based auto V/F optimization, capable of auto energy saving | ||

AVR | When the grid voltage fluctuates within a specified range, the inverter can automatically maintain a constant output voltage | ||

Auto Carrier Regulation | Auto carrier regulation based on load characteristics and ambient temperature | ||

Random PWM | Tone adjustment for an operating motor | ||

Instantaneous Power Failure Solution | Uninterrupted operation via busbar voltage regulation in the event of an instantaneous power failure | ||

DC Braking | Braking time: 0.0-60.0s; braking current: 0.0-100.0% of rated current | ||

PFI | Max input frequency: 50kHz | ||

PFO | Connector open circuit-type pulse square wave signal output; programmable | ||

Analog Input | 3-channel analog signal input; options for voltage/current modes; capable of positive/negative input | ||

Analog Output | 2-channel analog signal output; options for 0/4-20mA or 0/2-10V; programmable | ||

Digital Input | 8-channel multifunctional digital input | ||

Digital Output | 2-channel multifunctional collector open-circuit output; 5-channel multifunctional relay output | ||

Communication | Inbuilt RS48S communication interface supporting Modbus protocol and USS commands | ||

Feature | Process Identification | Two PID parameter systems and multiple correction modes | |

Water Supply Mode | Multiple water supply modes: fire water control, water injection control, clean water pool inspection, wastewater pool inspection, drainage pump control, sleeping, pump change at regular intervals and pump overhaul | ||

Custom Menu | 30 user parameters can be customized | ||

Change of Parameter Display | Parameter display different from the factroy settings is supported | ||

KWH Meter | Convenient for adjustment of the optimized energy saving schemes | ||

Protection | Protection is available for overcurrent, overvoltage, undervoltage, input/output phase lack, output short-circuit, overheat, motor overload, external fault, analog input disconnection, stall prevention, etc. | ||

Fittings | Braking units, extension cords for control panel, remote control box, digital I/O extension boards, relay extension boards, control panel capable of parameter copying (SB-PU70E) and LCD- display control panel (SB-PU200) | ||

Environment | Application | Indoors; an elevation below 1,000m; away from exposure to direct sunlight, dust, corrosive gases, combustible gases, oil mist, water vapor, drippings and saline mist | |

Ambient Temperat- ure/Humidity | -10-+40℃/<90%RH; no condensate or dew | ||

StorageTemperature | -20-+60℃ | ||

Vibration | Below 5.9m/s2 (0.6g) | ||

Structure | IP Rating | IP20 | |

Cooling Mode | Force air cooling with fan control | ||