SB150 is a compact inverter adopting the optimized high-performance space vector control VVVF arithmetic and featuring elegant appearance, delicate circuit design, ingenious circuit design, simple and practical functions, and reasonable menu arrangements.

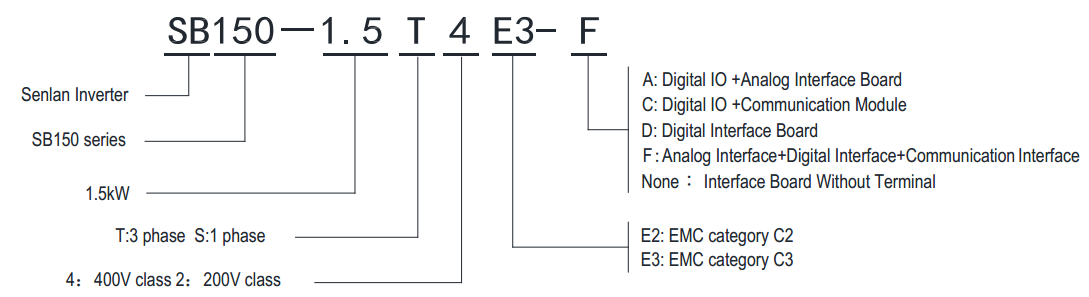

SB150 Inverter Model Description:

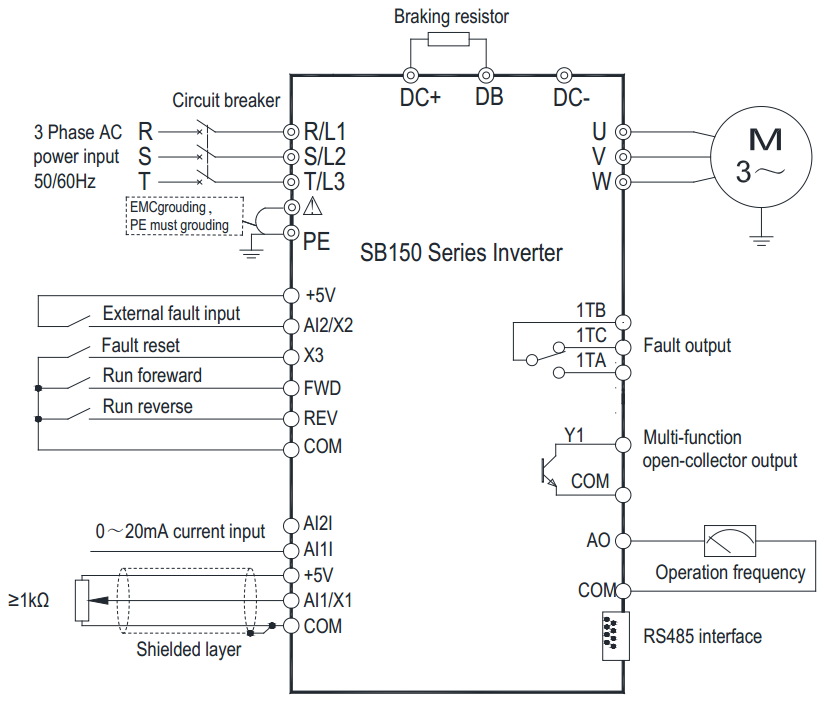

Basic wiring diagram is shown as below:

Common specifications for SB150 series

Item | Description | |

Input | Rated voltage and frequency | 3-phase: 220V/380V, 1-phase 220V~240V 50/60Hz |

Allowable range | Voltage: -15%~10%, voltage imbalance<3%, frequency: 47~63 Hz | |

output | Output voltage | 3-phase, 0V~input voltage, with the error less than 5%. |

Output frequency range | V/F control: 0.00~650.00Hz Vector control: 0.00~200.00Hz | |

performance standard | Overload capacity | 150% of rated current for 1 minute |

Frequency resolution | Digital reference: 0.01Hz Analog reference: 0.1% of max. frequency | |

Output frequency precision | Analog reference: : ±0.2% of max. frequency(25±10℃) Digital reference: 0.01Hz | |

Control terminal | Communication | Built-in RS485 port, supporting Modbus protocol |

Analog input AI | 2 channels AI(also used as digital input),voltage or current type, positive or negative, with drop detection | |

Analog output AO | 1 channels AO, voltage or current type independent terminal to choose | |

Digital input | 5 channels of multi-function digital input(two of them are analog inputs),sampling period 1ms | |

Digital output | 1 channel of NPN multi-function digital output,1 channels of multi-function relay output | |

Software function | Motor control mode | Space vector V/F control, with auto torque boost and slip compensation |

Command source | Keypad, terminal and communication. They can be switched over by terminals | |

Frequency reference source | Keypad(keys and POT), communication, UP/DOWN value, AI1, AI2. Auxiliary frequency reference can be introduced for fine tuning | |

V/F curve | Linear curve and two reduced-torque curves, with manual and auto torque boost | |

Dynamic braking | Built-in braking unit and external braking resistor | |

DC braking | Braking time: 0.0~60.0s Braking current: 0.0~100.0% of rated current | |

Accel/Decel | Linear or S-curve acceleration/deceleration | |

Jog | Jog frequency: 0.10~50.00Hz | |

AVR | Keeps the output voltage constant automatically when the voltage of power grid fluctuates | |

Auto carrier regulation | Carrier frequency is regulated automatically based on the load characteristic and ambient temperature | |

Momentary power failure | Ensures uninterrupted operation by controlling the DC link voltage | |

Process PID | process PID adjustor, can do 4 references, can disable terminals, and provide PID revise mode, sleep function (suit for water supply industry) | |

Wobble | Ensures even winding of textiles | |

Multistep frequency | 7 multistep frequencies, selected by digital input terminal. | |

others | Smooth start, stall prevention, zero-speed delay, oscillation suppression, deadband compensation | |

Protection functions | Over-current, overvoltage, under-voltage, input/output phase loss, output phase short-circuit, overheating, motor overload, external fault, analog input disconnection, stall prevention, etc. | |

Options | Braking resistor, input/output reactor, DC reactor, EMI filter, Profibus-DP module, remote control box, LCD keypad etc. | |

Ambient | Service site | Altitude less than 1000 meters, indoor, no direct sunlight, free of dust, corrosive gases, inflammable gases, oil mist, water vapor, water drops, salt mist, etc. |

Temperature/humid | -10~+40℃/20~90%RH, no condensation | |

Storage temperature | -20~+60℃ | |

Vibration | Less than 5.9m/s2(0.6g) | |

Structure | Protection degree | IP20 |

Cooling method | Forced air cooling, with fan control | |