As the world's largest coke producer, China's average annual coke output exceeds 450 million tons, accounting for more than 68% of the world's total output. Traditional wet coke quenching cannot meet environmental protection requirements and runs counter to the "double carbon" goal. Dry coke quenching has been widely used due to its advantages of high energy utilization and significantly reduced exhaust gas emissions.

As a key equipment, the CDQ elevator has extremely high requirements on system control performance, reliability, and safety. Its electronic control system has been dominated by imported brands for a long time and is in urgent need of upgrading.

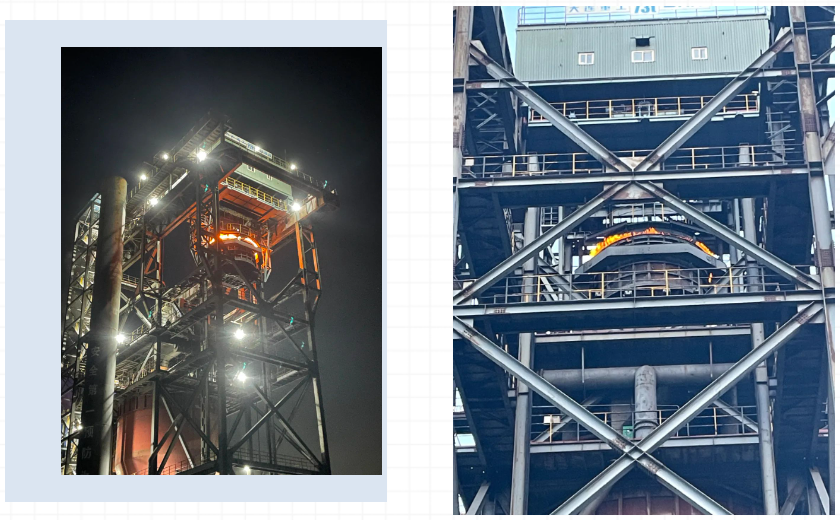

Recently, a company in Ningxia upgraded its coke oven, and all the work could only be completed during a short shutdown period for maintenance. It faced problems such as tight time, heavy tasks, and strict requirements. In addition, the original imported equipment data information is seriously missing, and the system operation process, protection, etc. need to be reorganized, making debugging extremely difficult. SLANVERT once again demonstrates its core competitiveness in the field of industrial transmission with its strength.

Engineers from SLANVERT’s “Tiejun special engineering department” rushed to the scene as soon as possible. With their professional technical level, hard-working spirit, and unremitting and continuous struggle, they provide customers with effective solutions and provide reliable guarantee for the resumption of production after maintenance.

SLANVERT customized two four-quadrant frequency converters SB70G315Q4CT dedicated to the hoist for this project. They adopt dual frequency conversion master-slave mode and support collaborative control and independent control. Coupled with high-performance vector control technology, the current impact of heavy-load starting of the motor is reduced, with high synchronization and good power balance, achieving the strict process requireme.

Founded in 1998, SLANVERT is a national-level high-tech enterprise specializing in energy conservation & environmental protection, new energy sources, transmission control, and intelligent equipment fields. The company integrates R&D manufacturing, system integration, and customer service to deliver comprehensive solutions. Its product range includes high/low voltage variable frequency control systems, automation production lines and robot transmission control systems,EPS (Emergency Power Supply) units,port shore power systems,multi/single crystal silicon power supplies,and other industrial power supply systems. With over 20 years of dedication to excellence under their business philosophy of "Excellence without Boundaries,Infinite Hope", SLANVERT products are now distributed across more than 30 countries including China , India,South Africa,Brazil ,Italy ,Denmark,Singapore ,Indonesia,Malaysia,Vietnam,Turkey etc.